Title

Title

Documents

EDGLZD8-T1-0C-NO-0-GN/RD

28.5MM RECESSED CAPACITIVE TOUCH SWITCH, ALUMINUM ANODE COLOUR LED RED/GRN, M8, 4-POLE, 24VDC, NO

Device Type

Connector

Connector Pin Count

Connection Type

Rated Voltage

Housing Colour

LED Colour

Capacitive Touch Switch

M8

4-Pin

NO

24V DC

Aluminum Anode

Red/Green

Pilot Devices by Eco-Drive Max offer exceptional performance and reliability at an industry leading cost.

Configurator

Motor Type

Horsepower (HP)

Mounting

RPM

Voltage

Motor Box Orientation

Frequency

Factory Encoder Mods

Your EDM Part #:

Model not Found

Description:

1HP, 1200, 190/380V, Foot Mount, 60Hz, F1, Cast Iron, SF1.15, CT 10:1, TEFC, Premium Efficiency Motor, NSK Bearings, IP55, B3, Ins. Class F, CSA Approved, Encoder Mount for Dynapar HS35R102484P7, Shaft Output To Be 5/8 Inch (0.620 Inch)

List Price:

C$14.99

Your Price:

C$9999.99

Available:

Loading...

Gearbox Characteristics

Output Shaft Loads

Output Torques

Input Speeds

AB Series High Precision Planetary Gearbox Basic Dimensions

Features

-

TEFC

-

NEMA Frames

-

Inverter Duty Rated: 10:1 CT (Constant Torque)

-

Service Factor: 1.15

-

NEMA B design

-

Protection Degree: IP55

-

Enclosure: TEFC Rigid Cast Iron Frame

-

VPI applied for best electrical performance

-

Corrosion resistant epoxy coated

-

Foot mount or Foot mount with C Flange

-

1HP to 250HP

-

F1 / F2 Convertible

-

Oversized NSK bearings on both ends (444T and up DE Roller Bearing)

-

230/460V 50/60Hz, usable at 208V (444T and up 460V only)

-

575V 50/60Hz

-

4, 6 & 8 Pole (1200RPM, 1800RPM, 3600RPM)

-

Class “F” insulation with rise below Class “B”

-

Stainless Steel option

-

CSA-US certified, DOE approved

Performance DatA

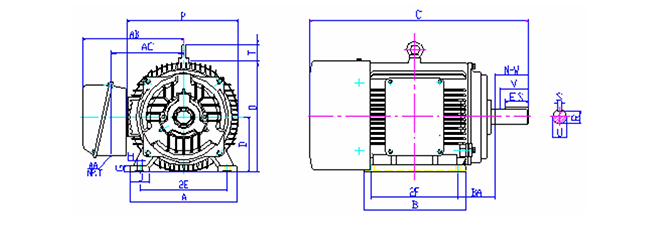

Foot Mounting Dimensions

Face Mounting Dimensions

Please Note:

1. Tolerance on dimension D: +0.000", -1/32" for frames 143 ~ 326

+0.000", -1/16" for frames 364 ~ 449

2. Tolerance on Shaft Diameter U: +0.000", -0.005" for frames 143 ~ 215

+0.000", 0.001" for frames 254 ~ 449

3. Tolerance on dimension R: +0.000", -0.015"

4. Dimension V is length of straight part of shaft

5. The conduit box can be rotated in 90° increments so that conduit can be received from any direction.

6. The conduit box can be located on either side of the motor

7. The last letter "Z" designates suitability for belt driven applications